Slat conveyors are used in a variety of sectors, particularly those where extreme conditions are experienced that would otherwise perish rubber or canvas systems and are renown for having a long-life with minimal repair & service. From twin-strand to apron slat assemblies and from piano hinged to those built bespoke to your requirements, you can rely on Chain and Conveyor to have the slats you need, and all the advice you need to operate and maintain them efficiently.

Slat conveyors can be used for horizontal conveying, inclined or escalator conveying, swan neck conveying or conveying over complex multiple sprocket systems. The type and design of slat is normally bespoke to the application but is usually a highly versatile solution for lots of applications.

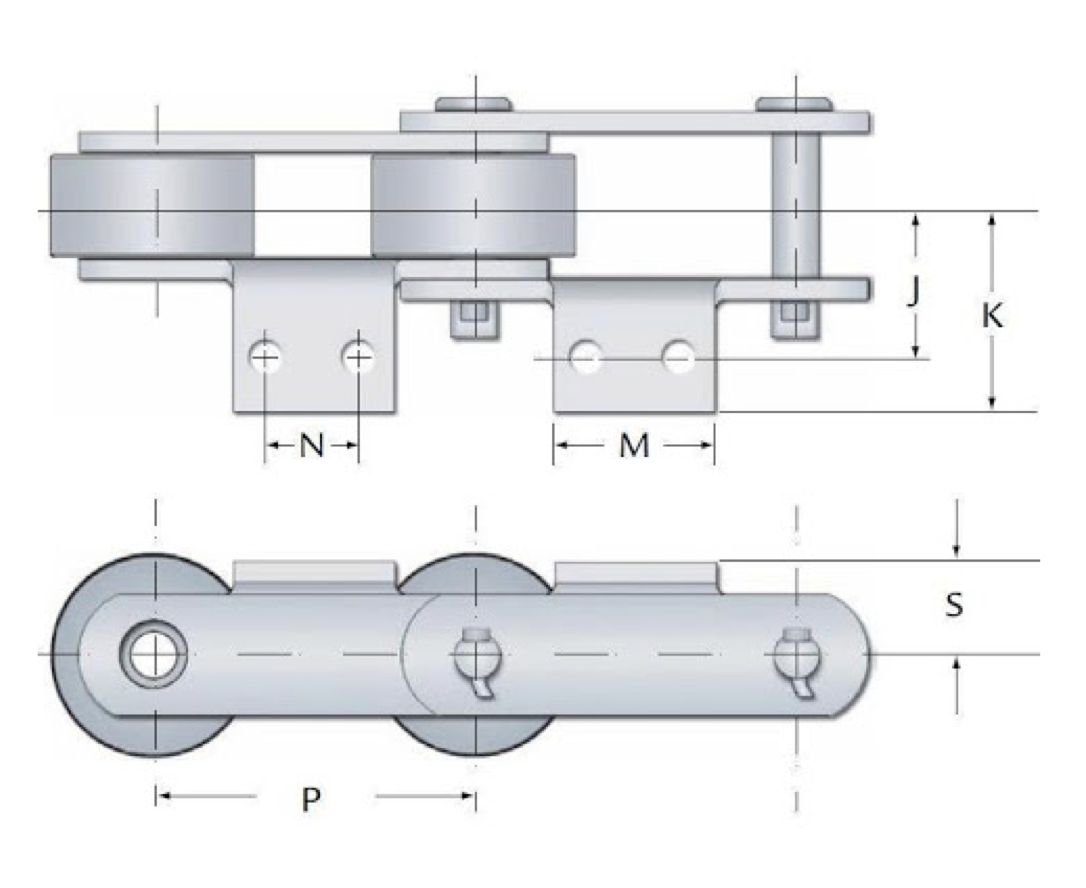

We offer a wide range of fully assembled twin-strand slatted chains to suit all aspects of mechanical handling.

Pressed channel and fabricated slats as shown available on chains from 50mm to 304.8mm pitch.

Pressed channel and fabricated slats as shown available on chains from 50mm to 304.8mm pitch.

Where conventional pressed or fabricated slats are unsuitable i.e. due to product spillage, apron or piano hinge assemblies can be employed. These utilise overlapping (apron) or interlocking (piano hinge) steel slats, supported by two strands of conveyor chain to form a continuous steel conveying medium.

We can also offer many of these components on an emergency breakdown basis. Even if we weren’t the original supplier, we can usually help identify a suitable and cost effective solution to get your conveyor system back up and running with minimal delay.